EQUIPMENT PRODUCTS

General Introduction

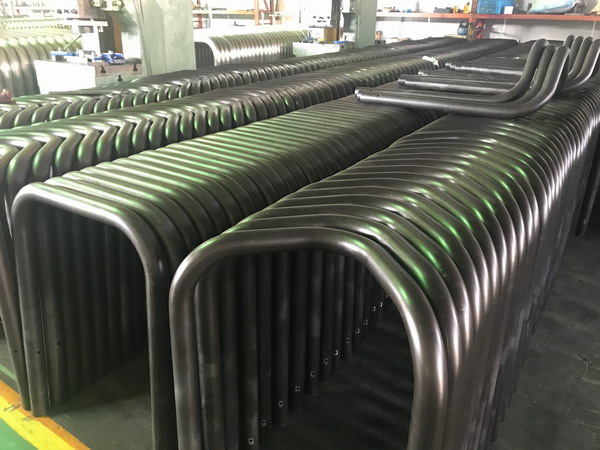

PB Style CNC Pipe Bender is the product ofKing-mazon cooperation with Addison. This CNC Pipe Bender use industrial computer and special software of CNC pipe bender, with multi axis servo controland servo hydraulic control. It has lots of functions,such as automatic feeding,automatic rotating,automatic changing tooling,automatic readdrawing,automatic edit and modify the process documents,automatic correctionrebound data,automatic loading and unloading,detect pipe precision,automaticreverse change process documents and process programme,automatic diagnosis fault, 3D pipe display and simulation, pipe virtual bending simulation, 3 Dinterference detection according to detecting result,etc.It can bend Max.tubeOD 114.3mm.This equipment use advanced computer to control machine's actions toimprove quality and effiency of products and reduce cost of product.Theequipment has high automation, high precision, high efficiency, low laborstrength, etc. PB Style CNC Pipe Bender and Electric Pipe Bender almost is thefirst choice for the field of aerospace, automotive, motorcycle, nuclearindustry, boiler, shipping building for cold bending. 1-5 stack tooling of PB Style CNC Pipe Bender is optional.

Feature Highlights

1. Multi-axis servo drive and IPCsystem equipment with high intelligence and automation. It can be processed bystretch bending or stretch bending plus pushing bending.

2. Single radius 3D bending withone pipe can be realized.

3. The manual, semi-auto and automaticoperation can be set.

4. The bending data can be inputdirectly to coordinate (X、Y、Z) or working data(Y、B、C).

5. There will be a 3D graphic model afterinput the bending data, and the bending process can be simulated for seeing thevirtual picture

6. The program image selfediting.

7. When editing the bending programs,some bends can be add or delete freely, and the editing programs can bememorized as a renamed program.

8. The storage of Max. bending programs anddata are unlimited.

9. During exam bending, choosing themicro-motion to observe the interfere point, then adjusting the movesto increasing the efficiency.

10. IPC control with 3D interferencesimulator.

11. The feeding style include clampfeeding and direct feeding

12. The feeding, bending and rotatingaxes all have multiple speed choices, for the same pipe, each bend can set thespeed individually.

13. The function of mandrel autooiling lubrication can be start or cancel by software.

14. The perfect machine defaults alarmingfunctions. The alarm message will be showed on screen. It is easy for searchingand clearing faults.

15. Multiple personal securityprotection is available.

16. 3D data reading and 3D digital measurement reverse compensation function

King Mazon CNC pipe bender can read 3D digital model (such as.* CATPart,.*STP) and automatically convert them into working parameters of the equipment. It has the function of calculating and compensating the bending springback database and the reverse compensation according to the actual value measured by the measuring instrument. Available for real-time communication with measuring equipment such as TubeInspect and articular arm measuring instrument, and compatible with actual bending data of catheter. It has the function of online measurement and automatic reverse correction of pipe bending process parameters. It is equipped with the interface to realize communication with the robot, so as to set up the production line with automatic feeding and unloading function of the robot.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号